Need Pricing quickly?

No problem, we have a Live team on hand to assist you. Click Start Now & enter your query.

![]()

No problem, we have a Live team on hand to assist you. Click Start Now & enter your query.

![]()

Versatile, Industry leading Mechanical Design. Shape the future with a complete portfolio of product development tools: mechanical and electrical design, simulation, manufacturing, technical publications, data management and more.

Solid Edge uses synchronous technology to help you accelerate product design, make revisions faster, and improve design data re-use. With faster 2D drafting, best-in-class sheet metal design, flexible part and assembly modeling, built-in photo-realistic rendering, and unmatched mobility, Solid Edge transforms your business. Plus, getting up to speed and using the platform is fast. We can support your usage with a wide range of training courses we provide also.

The engine behind Solid Edge is Siemens Parasolid® software, the most widely used computer-aided geometric modeling kernel in the industry. Parasolid delivers 100 percent 3D model compatibility between product development applications. By enabling the creation and modification of digital 3D models, Solid Edge delivers on the Siemens commitment to provide digital transformation capabilities to its users. Digital transformation allows even the smallest organizations to leverage technology to level the playing field with large enterprises.

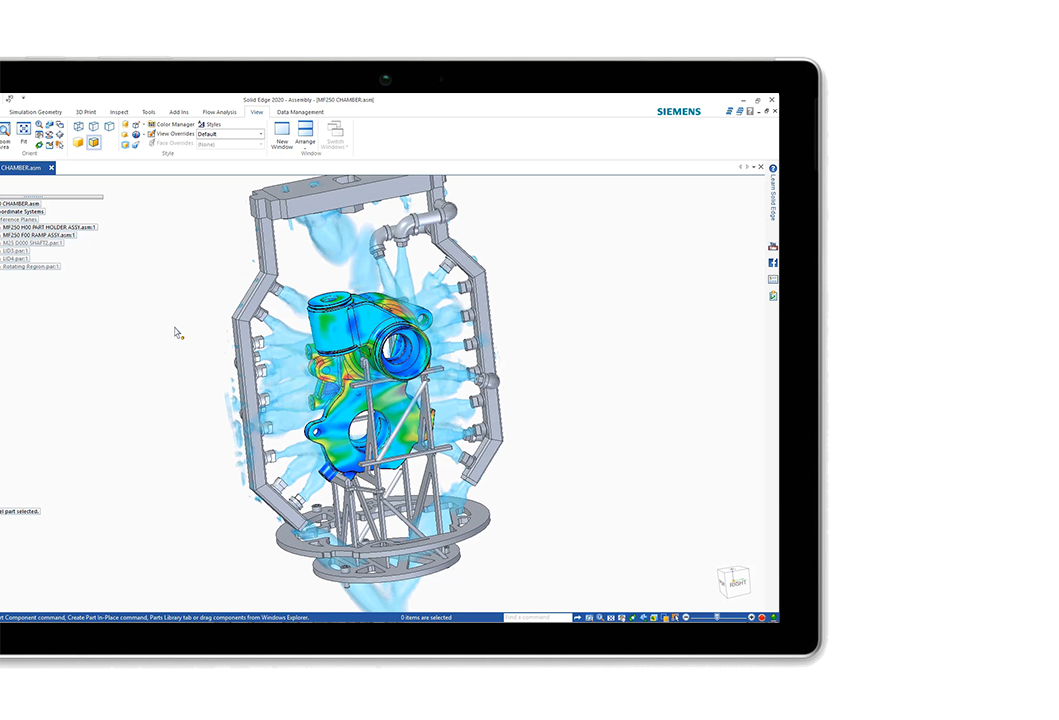

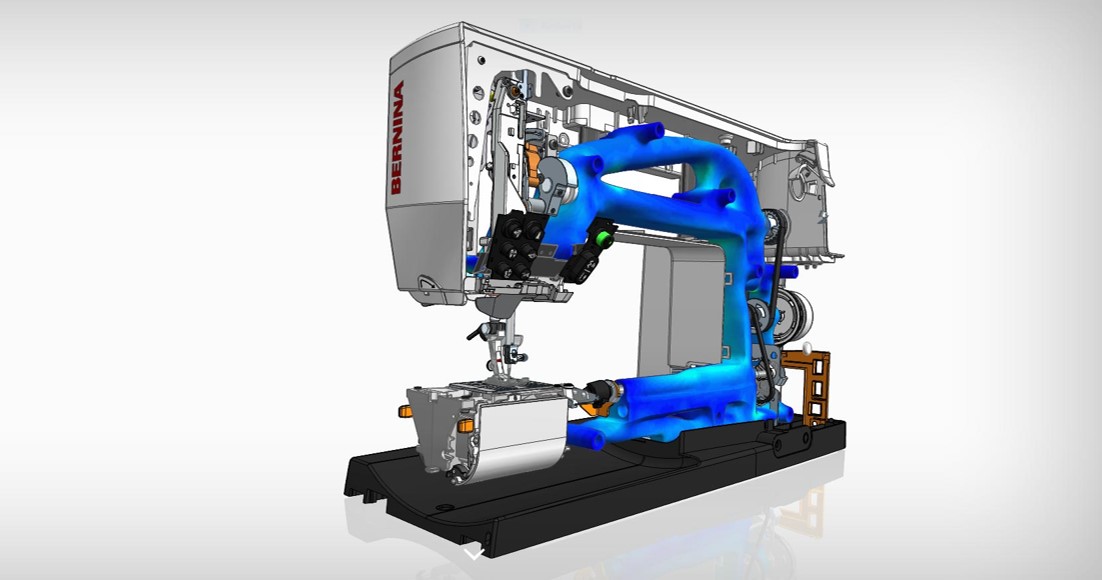

Simulation capabilities for Solid Edge users include simulation of individual parts, assembly analysis, definition and analysis of complete systems and computational fluid dynamics (CFD).

By starting simulation early in design, changes are made when they are easiest, time-to-manufacture is shortened, and cost-to-manufacture can be reduced. And accurate simulation of complete models reduce the number of physical prototypes and further reduce time and cost.

Solid Edge simulation offers built-in finite element analysis (FEA) allows design engineers to digitally validate part and assembly designs within the Solid Edge environment. It also offers the ability to use FLOEFD, enabling design engineers to frontload computational fluid dynamics (CFD) analysis or move simulation early into the design process where it can help examine trends and eliminate less desirable design options. Finally, Solid Edge Femap, an affordable high performance FEA modeling for the engineering desktop. Femap is recognized as the world’s leading CAD-independent Windows-native pre- and post- processor for advanced engineering finite element analysis.

Solid Edge allows you to fully take advantage of additive manufacturing, whether you are creating individual prototypes or manufacturing larger volumes of components. Our tools support your end-to-end workflow, from design-for-manufacture using additive techniques, to preparing and outputting your designs to 3D printing hardware and services.

Generative design combines powerful design tools with topology optimization, speeding the creation of lighter components perfectly suited for immediate manufacture via additive processes. Solid Edge seamlessly combines traditional “b-rep” solid models with triangular mesh models without time-consuming and error-prone conversions, reducing rework while supporting modern additive manufacturing processes for complex shapes.

Solid Edge supports output of your part models to 3D Printers using the 3D Print command. Write out your parts to .stl and .3MF formats, or send your parts directly to the Microsoft 3D Builder app. This allows you to print in-house with automated print preparation, including color printing capability.

Bring ideas to life with design visualization. Solid Edge Augmented Reality allows users to experience true-scale digital prototypes in real-world environments, connecting the digital environment with the physical world. This allows a design to be showcased in its intended environment in a compelling way, even before it is built.

This feature allows you to benefit from; free, easy access to next generation virtualization, communicate design intent in intended physical environment, assist in design collaborations, secured sharing and the ability to extend augmented reality to other augmented, virtual and mixed-reality experiences. This diverse set of capabilities really allows you to maximise your 3D experience by stepping into world yourself.

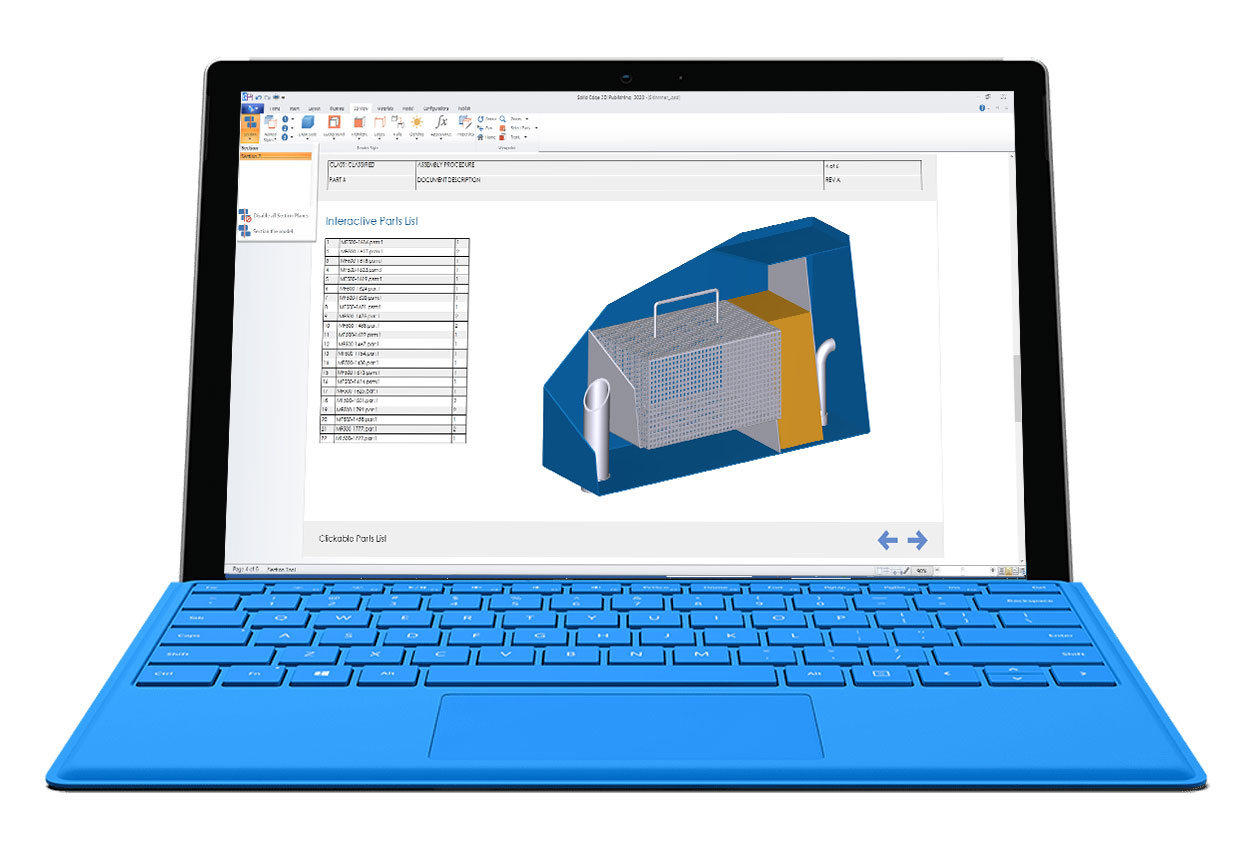

The ability to clearly communicate the correct manufacturing, installation and maintenance procedures for your designs is essential to the performance of your products and the success of your business. Using Solid Edge technical publications solutions, your designers can quickly create many types of technical documents—from simple illustrations for end user manuals to interactive 3D technical documents for manufacturing and service. You can reduce the need for specialist technical authors or external services and produce top quality documents in-house.

Solid Edge Illustrations allows you to create high-quality 3D PDF documents and cloud-ready illustrations from your Solid Edge files and other 3D CAD formats. Use Solid Edge to capture 3D views then add features including markups and balloons before publishing. Solid Edge Illustrations provides a complete image, animation and template-based 3D PDF creation package, making it easy to create high-quality communications from your 3D models.

Solid Edge 3D Publishing includes a powerful set of tools for working with 3D CAD models, parts lists and formatted text allowing anyone to author complete printed or interactive technical documents in minutes. Perfect for creating training and work instructions, illustrated parts catalogs, service and support documentation, and product manuals.

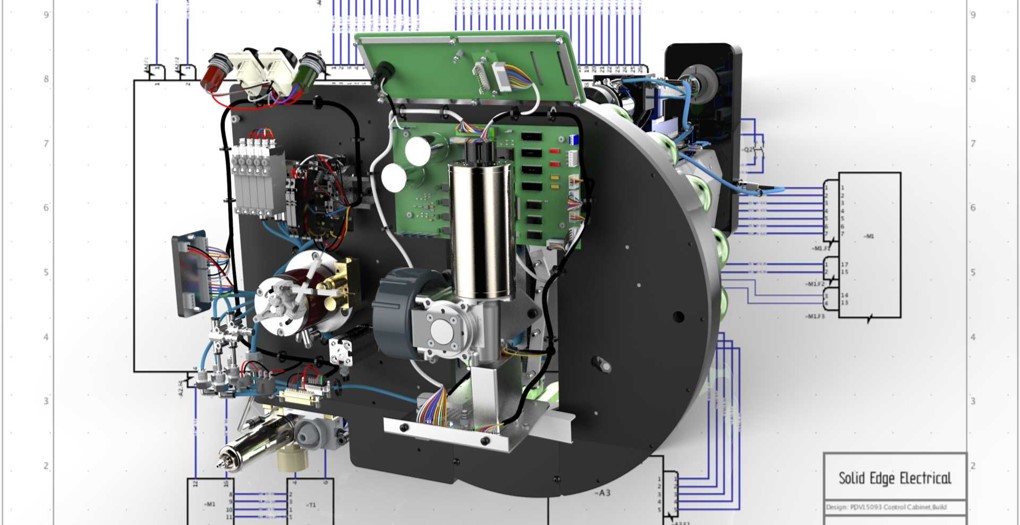

Solid Edge helps you overcome electromechanical design challenges with a dedicated solution for electrical design—enabling true co-design collaboration across electrical and mechanical domains. Based on industry-leading technology from Mentor Graphics, a Siemens business, our products are trusted and proven around the world.

Create fully functional and manufacturable electromechanical designs in a seamless ECAD-MCAD environment where changes are highlighted interactively in both domains, minimizing design errors and shortening development time.

Contact us for more details, we can setup a technical call and cover any element and show you how it can benefit your current processes.

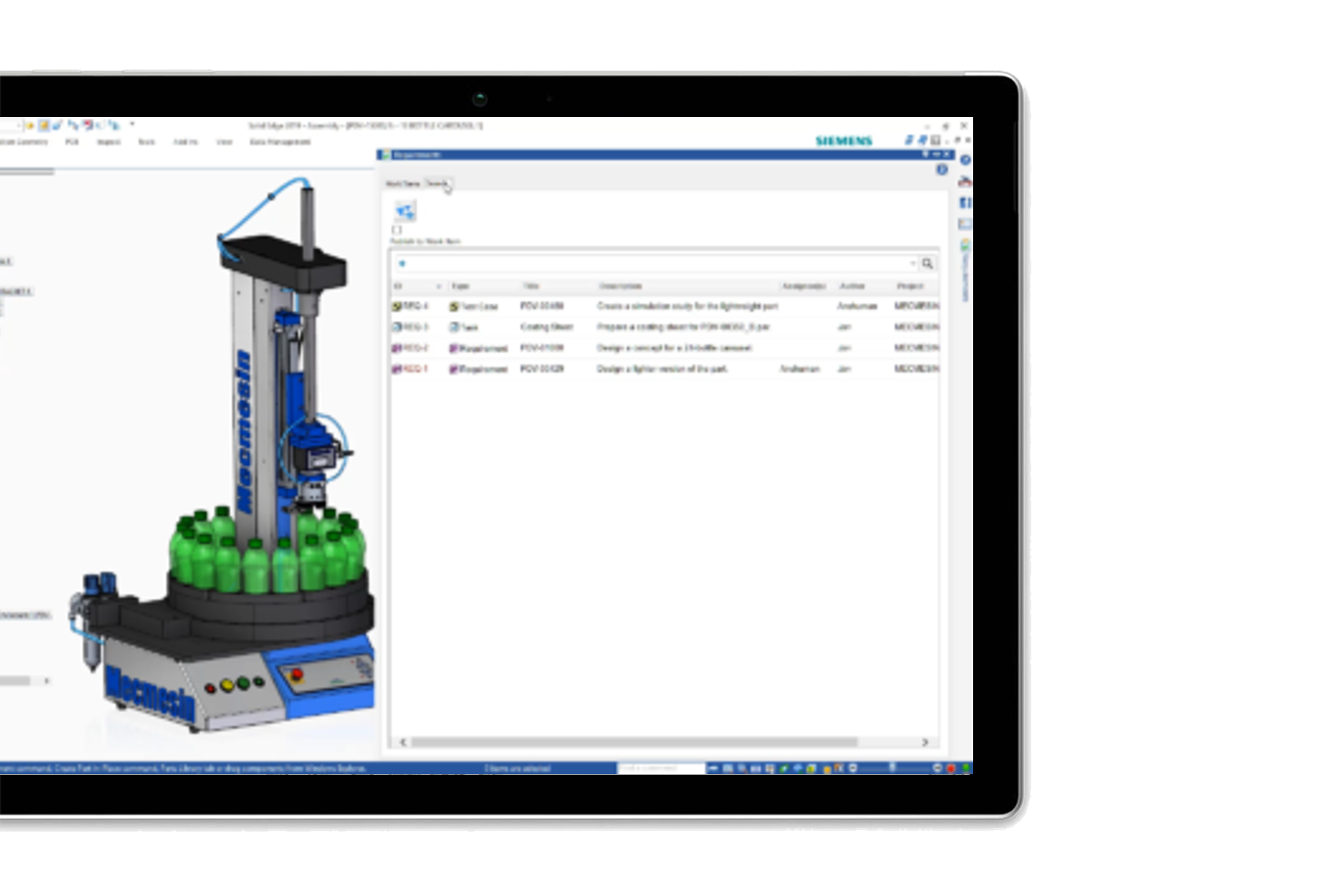

Solid Edge Requirements Management allows you to accurately link and track requirements during the product design and manufacturing process, helping you to deliver a successful product.