Need Pricing quickly?

No problem, we have a Live team on hand to assist you. Click Start Now & enter your query.

![]()

No problem, we have a Live team on hand to assist you. Click Start Now & enter your query.

![]()

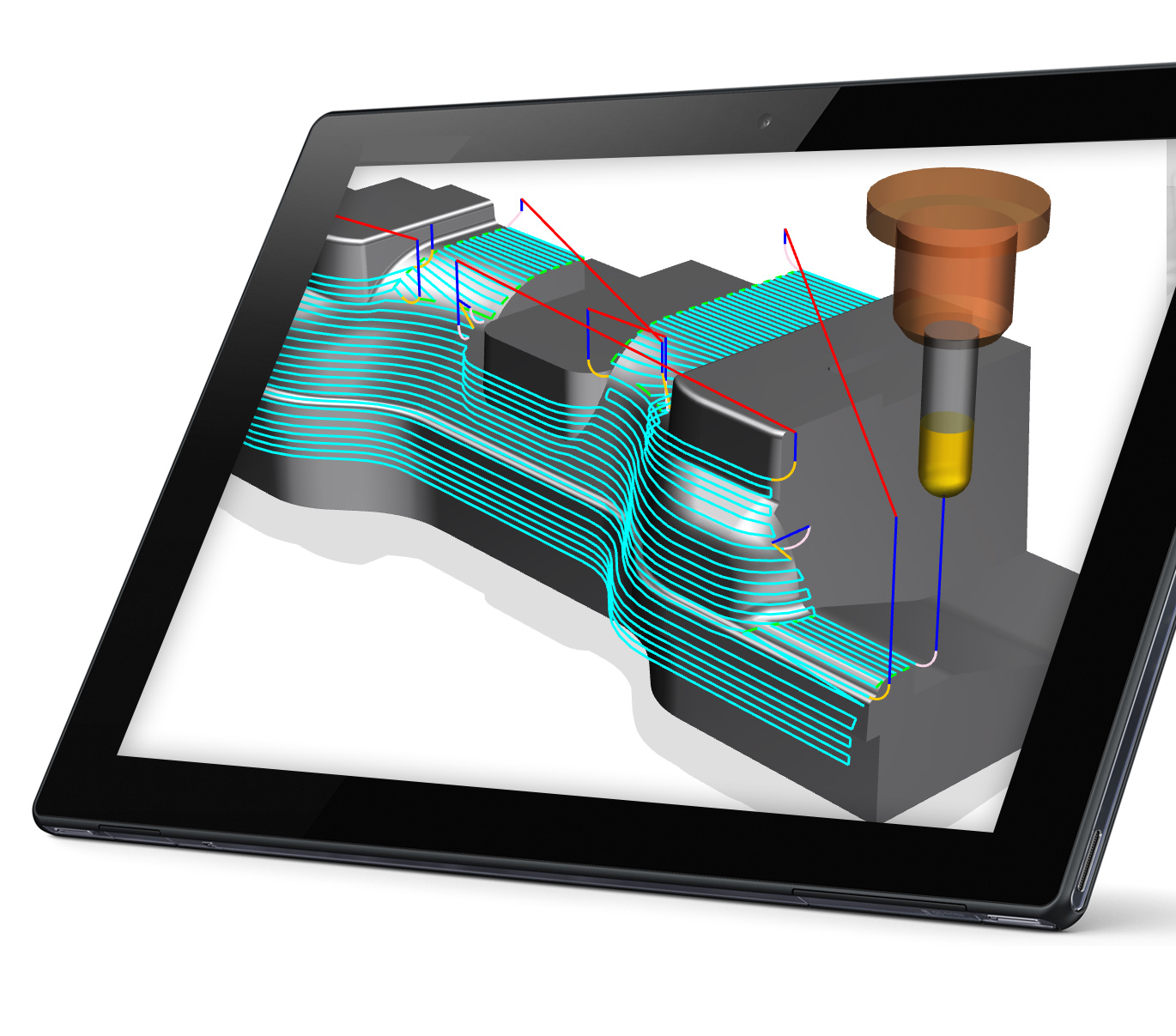

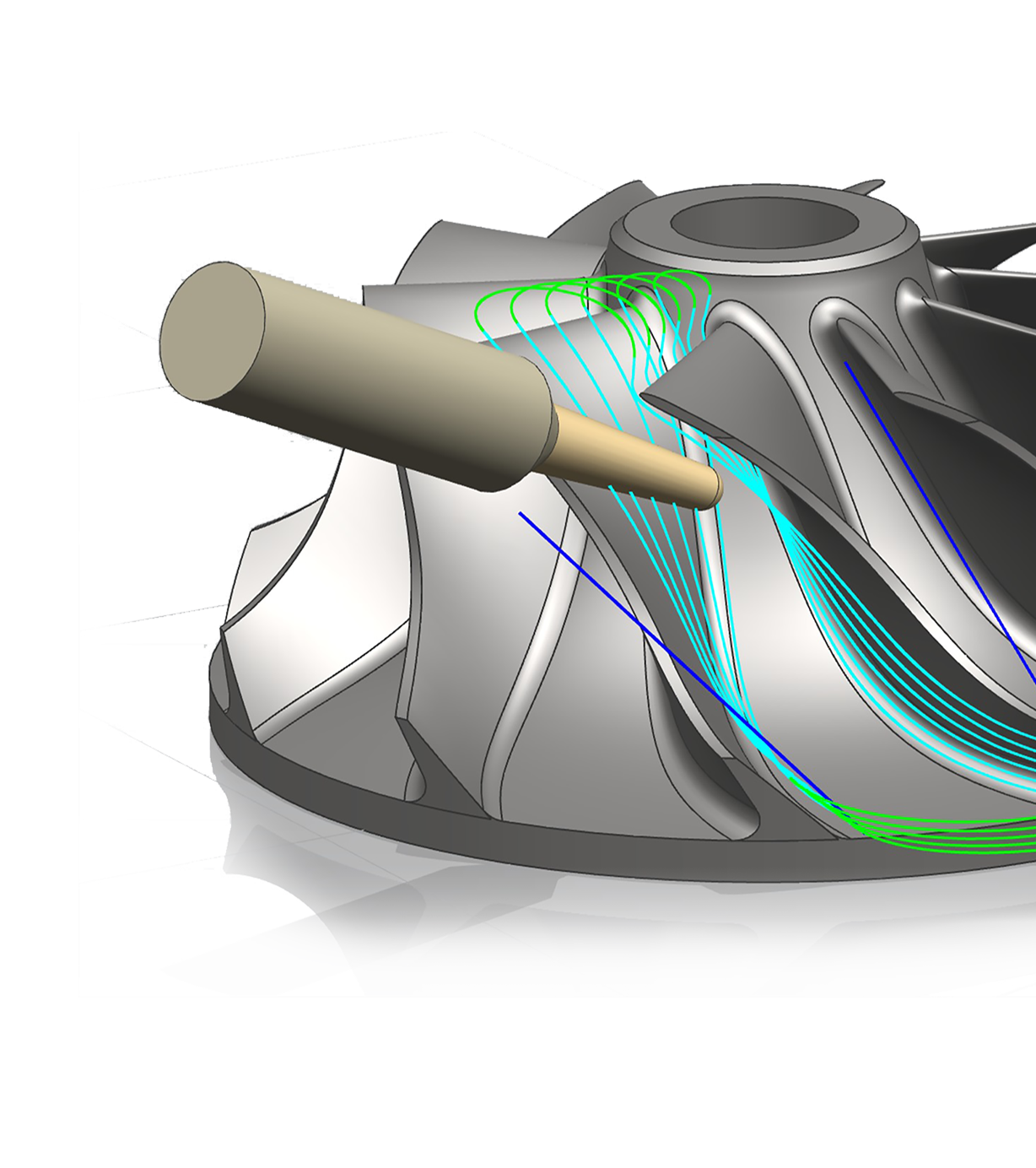

Poor quality geometric data imported from other systems can cause programming issues. For example, mismatched edges, tiny gaps in faces and non-manifold conditions are common in lower-precision modelling tools.

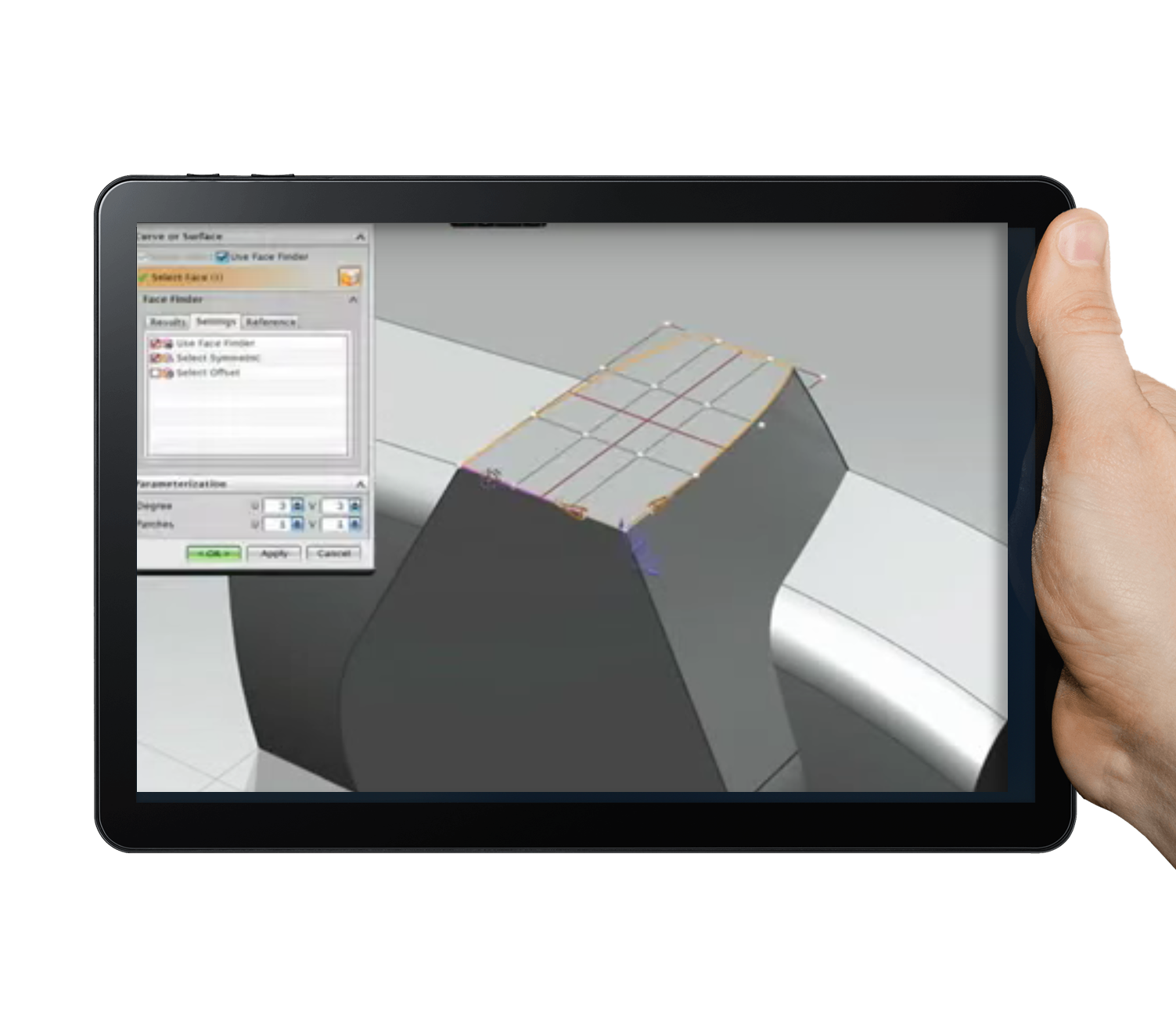

With complete consistency across the NX platform, you can easily access the NX CAM advanced functions.