Need Pricing quickly?

No problem, we have a Live team on hand to assist you. Click Start Now & enter your query.

![]()

No problem, we have a Live team on hand to assist you. Click Start Now & enter your query.

![]()

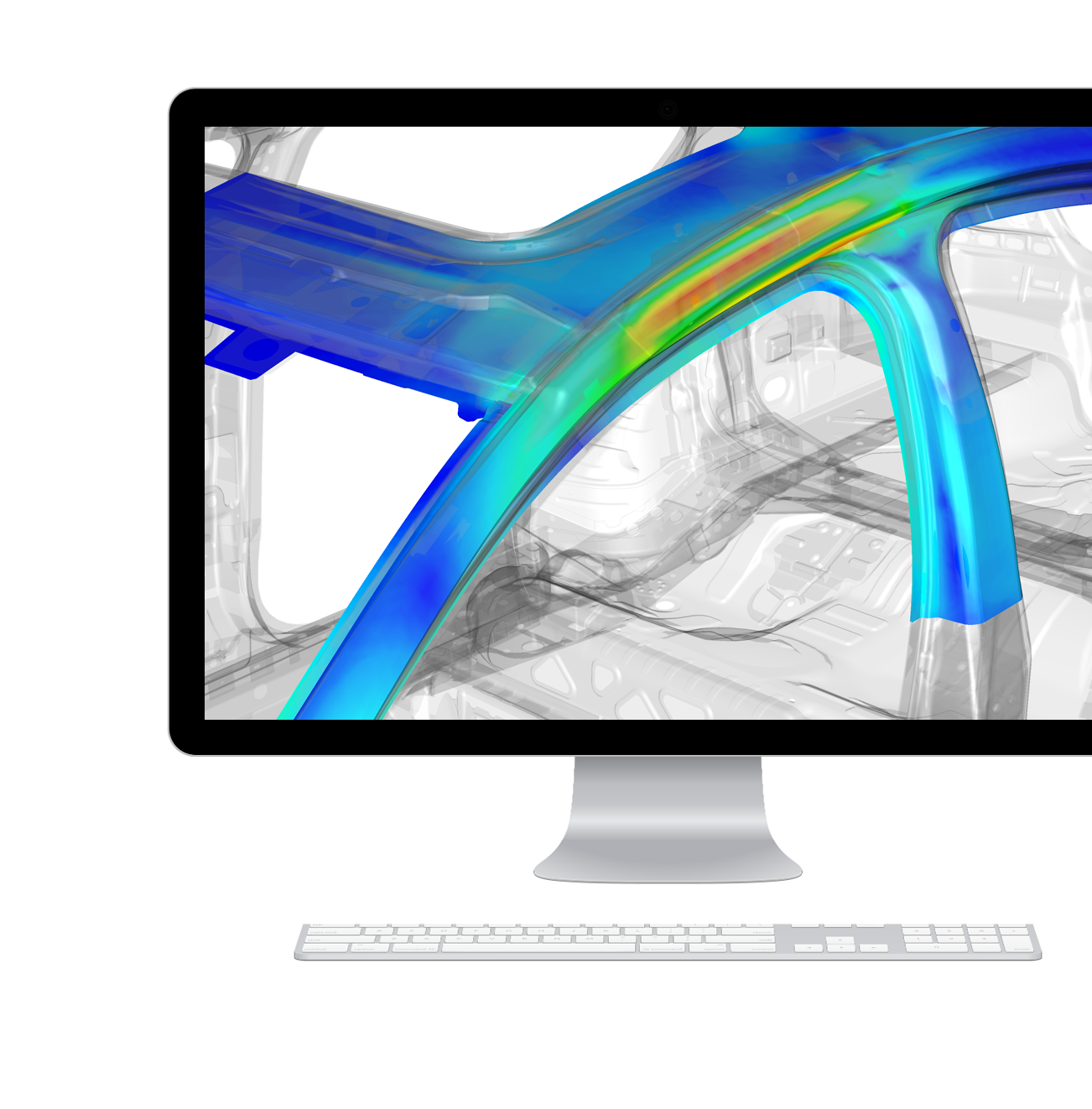

FE model in context expands upon Simcenter’s unique, distributed environment for building analysis model assemblies by allowing you to edit a single finite element component model quickly in the context of the overall assembly. In NX CAE, you can set the ‘work’ part independently of the displayed part, which allows you to see and reference the rest of the FE assembly while editing just the FE component model.

Mid-surface enhancements provide a better result on the first pass, and ultimately allow you to create mid-surfaces up to five times faster. Some of the new enhancements to the mid-surface command include a new ‘rolling ball’ thickness calculation algorithm, which provides more granular thickness information throughout a body.

…lets you drive the design towards an optimal solution by varying design geometry. This is useful for trade-off studies and to determine optimum operating conditions for a product, such as the need to minimise the temperature of a critical component within an electronic device through variation of airflow patterns.

Edge-to-edge glue support for NX Nastran is a simple and effective method to join dissimilar shell meshes. Glue connections between the edges of shell elements in the same plane simplify the modelling process for you, without compromising the accuracy of the structural analysis.

Bolt pre-loads on solid elements for NX Nastran allow more detailed representations of bolts, including contact between hole and bolt, which will give you more accurate results.

Import Fibersim HDF5 files into NX laminate composites to obtain more information for each ply than is available in the XML file, such as the draping starting point, direction and orientation angle.

Multi-threading takes advantage of multi-core and multi-processor hardware, and speeds up the thermal computations. Multi-threading is most useful for radiation-dominated models. For transient runs, depending on output intervals, run time can be reduced by up to about 25 percent (using four cores).

New fully coupled scheme for parallel flow solver helps to solve large models faster. This fully coupled pressure-velocity scheme is now used by default, and is better suited for solving steady-state models or transient models using larger time steps.

…means you can seamlessly and efficiently move from CAD assembly to a motion study using a flexible body. You can then use the results of the motion simulation to kick off a durability analysis on the component in question.

Further, you can quickly simulate design alternatives by suppressing/unsupressing individual motion objects and dependent objects from the active solution.